-

Rolling Process

-

Coating and Processing Lines

-

Slugs

-

Recycling

-

Cutting

-

Tubes

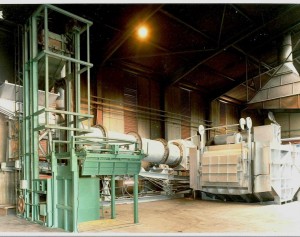

Aluminium Recycling Plants

Aluminium Scrap Recycling plants

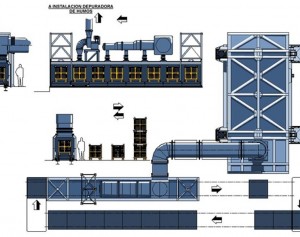

GENERAL BASIC INFORMATION OF THE PLANT CONFIGURATION

INCO technology in secondary aluminium allows the end user to get final products with an important added value in respect of the LME Price, thanks to an extreme control in the metal losses while recycling.

Our recycling process for aluminium scrap is made of a preparation and preheating section before melting.

Scrap delacquering and preheating system work with the melting section and, therefore, transform the aluminium scrap in:

The starting raw material can be:

INCO technology is based on the following principles:

INCO technology in secondary aluminium allows the end user to get final products with an important added value in respect of the LME Price, thanks to an extreme control in the metal losses while recycling.

Our recycling process for aluminium scrap is made of a preparation and preheating section before melting.

Scrap delacquering and preheating system work with the melting section and, therefore, transform the aluminium scrap in:

- Extrusion billets

- Aluminium ingots

- DC casting slabs

- Continuous casting coils

The starting raw material can be:

- Scrap (painted/lacquered or without paint) coming from the market

- UBC (used beverage cans)

- Extrusion ends and extrusion profiles scrap

- Cables, Sheets, Lithographic sheets

- Chips from machining

INCO technology is based on the following principles:

- Minimum melting losses.

- Strict productive ratio control by using minimum number of personnel.

- Minimum production equipment cost, which let you make acceptable pay back terms.

- Maximum energy harnessing (recovering most of the heat surplus from melting) and maximum power rationalization.

- Automation utmost improvement so as to improve the number of operations involved.

INCO is made up of a group of companies specialized in engineering and manufacturing of equipment and machinery for metallurgical processes for both ferric metals as well as for non-ferric metals. We focus our experience and capabilities in the equipment for the transformation and the increase of value of flat products (coils), covering also the melting and casting processes for non-ferrous metals as aluminium or copper.

INCO is made up of a group of companies specialized in engineering and manufacturing of equipment and machinery for metallurgical processes for both ferric metals as well as for non-ferric metals. We focus our experience and capabilities in the equipment for the transformation and the increase of value of flat products (coils), covering also the melting and casting processes for non-ferrous metals as aluminium or copper.